The Star Called USAR

Oklahoma's rare earth magnet producer.

‘In the beginning YHWH (God) created the heavens and the earth.’ - Genesis 1:1

I write articles at Istoria on history, culture, and economics from a biblical perspective.

Some articles may not initially interest you, but I believe it's those articles that, if you choose to read them, will give you the most significant benefit.

This is one of those posts.

Continue reading if for no other reason than to understand that a guy like Stan Ralstin, whom you attend Bible Study with or whom you live next door to, is partially responsible for a unique, rare-earth magnet manufacturing company coming to Oklahoma.

Something very unique to the manufacturing world is happening in Stillwater, Oklahoma.

USA Rare Earth, Inc. (USAR) is beginning its production of rare earth Neodymium magnets in the first quarter of 2026.

Why Rare Earth Magnets Are Important

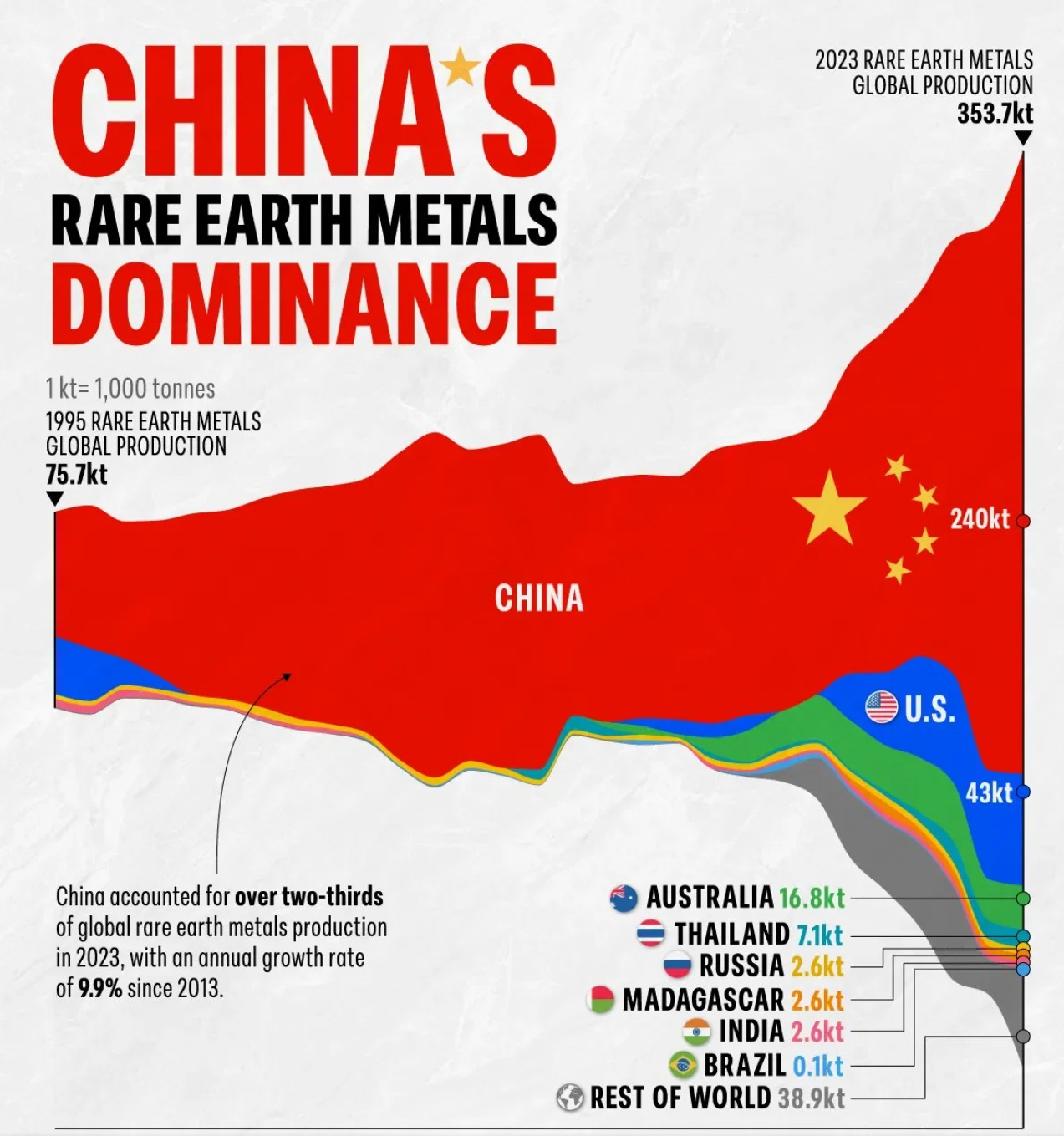

China’s overwhelming dominance in the production and processing of rare earth elements (REEs), controlling approximately 70-91% of global refined output, poses a profound national security risk to the United States by creating critical vulnerabilities in supply chains for defense technologies, renewable energy systems, semiconductors, and advanced manufacturing.

The U.S. imports over 70% of its REE compounds and metals from China, with only one operational domestic facility at Mountain Pass, California, where Beijing holds a partial stake, leaving American industries exposed to potential export restrictions or embargoes that could halt production of essential components like fighter jet magnets, missile guidance systems, and electric vehicle batteries.

Recent escalations, including China’s October 2025 export controls on REEs and magnets that prohibit shipments to U.S. defense contractors even with trace Chinese content, underscore this leverage, amplifying risks amid U.S.-China tensions and potentially crippling strategic sectors in a conflict scenario.

U.S. dependence on China for rare earth elements undermines U.S. military readiness, technological advances, and economic independence, as decades of Chinese investment in mastering REEs have entrenched Beijing’s position despite Western diversification efforts.

Rare Earth Magnets vs. Regular Magnets

Regular magnets are called ferrite magnets.

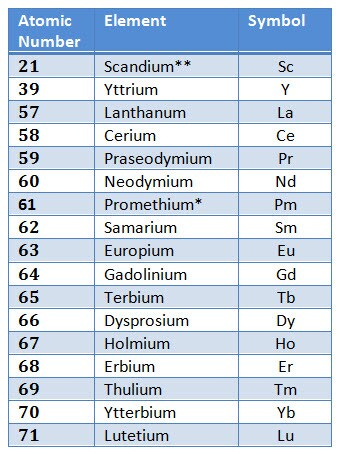

However, magnets made of rare-earth materials originated in the late 1960s, when US Air Force Materials Laboratory scientists discovered that an alloy of Yttrium and Cobalt had powerful magnetic properties.

Dr Masato Sagawa developed the first Neodymium magnets (NdFeB) in Japan, delivering exceptional performance and paving the way for a new era of magnetic technology.

Stillwater, Oklahoma, will become the first company in the United States to complete the entire process in the first quarter of 2026:

Mining rare earth metals at its Round Top (Texas) site, and then….

Producing rare earth Neodymium magnets at its 300,000 ft. processing plant in Stillwater, Oklahoma.

That’s a big deal for the USA, USAR, and those who know about rare earth magnets.

Here are 7 fundamental differences between regular and rare-earth magnets.

Composition: Regular magnets use iron oxide with strontium/barium; Neodymium (NdFeB) uses neodymium-iron-boron alloy.

Magnetic Strength: Neodymium magnets are up to 10x stronger than regular magnets, with an energy density of 200-440 kJ/m³ vs. 10-40 kJ/m³.

Size and Weight: Neodymium magnets enable smaller/lighter designs for equal pull, while regular magnets require bulkier sizes.

Cost: Neodymium rare-earth magnets cost 5- 10x more because the rare-earth elements they contain are more challenging to mine.

Temperature Resistance: Regular magnets withstand 250°C+; Neodymium magnets demagnetize at 80-200°C.

Corrosion Resistance: Neodymium rare-earth magnets require specialized coating to prevent rust, while regular magnets (ferrite) resist rust naturally.

Applications: Regular magnets can be used in cheap, bulky speakers, but Neodymium magnets fit compact, high-power applications like EV motors.

How Did USAR Wind Up in Oklahoma?

There are quiet, humble leaders in Oklahoma who get things done. Stan Ralstin is one of those people.

USAR, the rare-earth metals company in which I invest, is in Oklahoma due to Stan's efforts.

Stan, a native Oklahoman and a friend for over thirty years, is the recently retired Regional Development Specialist at the Oklahoma Department of Commerce.

With his permission, I’m sharing with you the story of how one of the most strategically critical rare-earth companies in the world landed in Stillwater, Oklahoma.

Keep reading with a 7-day free trial

Subscribe to Wade Burleson at Istoria to keep reading this post and get 7 days of free access to the full post archives.